Focusing Optics at Synchrotron X-ray Beamlines: Polish-to-Shape Mirror vs. Bent Mirror

The mirrors used in synchrotrons play a critical role in collecting and focusing the intense X-ray beams generated onto the tiny samples being studied. Inside a synchrotron, electrons are accelerated up to quasi-relativistic speeds, producing X-rays 10 trillion times brighter than those used in hospitals. These extremely bright light sources are what allow scientists to observe matter at the atomic level. In this kind of demanding environment, where precision and reliability are vital, choosing the right kind of mirror—polish-to-shape or bent—can improve synchrotron beamline performance.

Synchrotron mirror basics: polishing vs bending

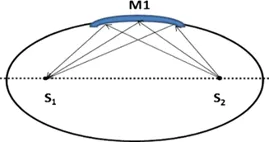

The beamlines inside synchrotrons can be up to 150 meters long to accommodate the complex opto-mechanical mirror systems required for the proper collection, energy election, and focusing of the X-rays onto the sample. The mirrors used are long, so that they can collect as much of the X-ray beam produced as possible, and their curve radii are very large—in the kilometers. The angle of incidence, which determines how the light will behave once it hits the mirror, has to be extremely low. These specifications can be obtained by either polishing or bending the mirror.

Synchrotron X-ray optics require integration into an ultra-high vacuum environment to avoid interference with ambient air. Polish-to-shape mirrors and bent mirrors each present their own challenges in terms of maintaining vacuum compatibility.

- Polish-to-shape mirrors: A single mirror and mounting support limit the potential outgassing surfaces in-vacuum.

- Bent mirrors: The integration of bending mechanics (motors, cabling) in-vacuum means additional outgassing surfaces. However, careful materials choices, the elimination of trapped volumes in the design, and “clean” assembly (UHV cleaning, assembly in cleanrooms) generally resolve any vacuum compatibility issues.

The ideal plan-elliptical mirror shape for latest-generation synchrotrons.

Vacuum compatibility: overcoming the challenges of more complex systems

Due to manufacturing tolerances and assembly errors, the nominally specified dimensions of a robot will differ from its actual ones. Given that, by default, the nominal model is used by the robot controller to calculate Cartesian positions from axis values and vice-versa, a discrepancy will occur between the position the robot thinks it has reached and its real position, leading to inaccuracy.

These uncertainties about the parameters describing the robot’s geometry are the main source of positioning errors. However, even with a geometric model as close to reality as possible, other sources of inaccuracy arise.

In particular, the bending deformations undergone by the robot links under the effect of their own weight and the mass of the tool can produce a deflection of the end-effector likely to considerably degrade accuracy.

Temperature variations, which cause the robot links to expand and contract, are also a major source of inaccuracy.

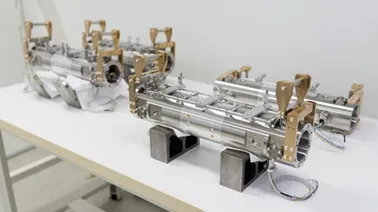

“Bender with encapsulated actuators that eliminate direct contact between the actuators and vacuum can certainly be as UHV-compliant as a mirror alone with its supporting mechanics.”

Irelec 4-cylinder mirror with encapsulated actuators.

Thermal stability: start by understanding thermal behavior

Operating under vacuum means there is no natural convection, making thermal behavior a crucial factor. It is important to understand that heat can come from the proportion of X-rays absorbed by the mirror and any actuators inside the vacuum chamber.

- Polish-to-shape mirrors: Thermally more stable but require cooling systems.

- Bent mirrors: The bending actuators must be close to the mirror, where they contribute to the thermal instability of the system. However, the bending actuators can also offset the thermal bump generated by the X-rays absorbed by the mirror, minimizing thermal-induced mirror deformation. The mirror-bender design is crucial here. A U-shaped bender will be much more sensitive to thermal effects than a 4-cylinder mirror bender, because of the long lever arms needed to obtain the desired bending resolution and the dilation of the arms, which directly impacts mirror curvature.

Mechanical stability: how well the system performs over time

Mechanical stability is essential for long-term experiments.

- Polish-to-shape mirrors: These compact and lightweight mirrors provide intrinsic stability.

- Bent mirrors: May be susceptible to mechanical drift over time. This can be minimized by encoding the bending operation as close as possible to the force/moment application region.

Profile accuracy: vital to optical precision

The shape obtained by polishing or bending must precisely match the optical configuration.

- Polish-to-shape mirrors: It is not easy to polish a mirror into the exact shape required, especially when high degrees of precision are required.

- Bent mirrors: A precision shape (distance to source & image, grazing incidence angle) is easier to achieve. In addition, a bending system allows for slight adjustments to compensate for thermal effects and for optical errors generated by upstream components.

Flexibility: how well the mirror system adapts to different configurations

Flexibility can be advantageous in certain experimental setups. A range of bend radii can accommodate various optical configurations.

- Polish-to-shape mirrors: No flexibility.

- Bent mirrors: Excellent flexibility.

Error topology: the ability to address mirror slope error

Mirror slope error is a major issue in X-ray beam optics. At such low angles of incidence, slope error—the difference between the actual slope of the mirror and the ideal slope—is the main indicator of mirror performance.

- Polish-to-shape mirrors: The polishing technique will have an impact on slope error, but once produced, polish-to-shape mirrors do not offer much leeway for slope error correction.

- Bent mirrors: By optimizing the bending moments, adding shape compensators, and using high-performance optical metrology procedures, error slope can be effectively addressed. For instance, beam striations due to long period slope errors when operating in defocusing mode can be suppressed.

Mirror weight compensation: how well the mirror system can compensate for weight effects

Effective counter-weight systems are important for both polish-to-shape and bent mirrors. For vertical focusing mirrors, in particular, the effect of the mirror’s own weight on longitudinal shape can be significant.

- Polish-to-shape mirrors: It is difficult to compensate for weight effects during polishing, and only a few mirror manufacturers offer this kind of correction. In most cases, a separate mechanical system has to be designed and integrated into the mirror support to effectively suppress this highly detrimental effect.

- Bent mirrors: Most commercially-available benders include a built-in counterweight system, offering a compact, integrated solution for suppressing weight effects.

Cost: mirror bender systems require a higher initial investment

The production price for polished conical mirrors is relatively high, but the cost difference between flat and plan-elliptical mirrors has narrowed over time.

- Polish-to-shape mirrors: Less expensive than mirror bender systems.

- Bent mirrors: These complete systems (flat mirror plus bending system) are more expensive to build and install. Depending upon the system, the additional cost is generally between 10% and 20%

Maintainability & upgrades: an impact on total cost of ownership

The maintenance of the optical systems is important to consider, particularly in latest-generation synchrotrons. Because there is no 100% effective solution for cleaning optics in situ, the cost and lead time for replacing a mirror should be factored into the total cost of ownership of the system.

- Polish-to-shape mirrors: Take longer and are more expensive to produce.

- Bent mirrors: Because mirror bender systems use flat mirrors (which are faster and cheaper to produce), they are more cost-effective to replace and/or upgrade. Bender systems do present maintenance challenges like drift over time (see “Mechanical stability” above), thus the importance of a bender system design that addresses this issue from the outset.

Polish-to-shape vs. bent mirrors: an informed decision is the right decision

In these cases, it is important to remember the benefits of mirror bender systems in terms of flexibility, error compensation, and maintainability—all of which reduce total cost of ownership.

To sum up:

| Polish-to-shape mirror | Bent mirror | |

|---|---|---|

| Vacuum compatibility | = | = |

| Thermal behavior | + | – |

| Mechanical stability | + | – |

| Profile accuracy | – | ++ |

| Flexibility | – – | ++ |

| Slope error correction | – | + |

| Mirror weight compensation | – | + |

| Cost | + | – |

| Maintainability | – | + |