Synchrotron

Single Crystal X-ray Diffractometer

The new generation diffractometer: Bespoke, Smart and Swift

Over the past decades, X-ray crystallography has undergone successive technological breakthroughs: hybrid photon-counting detectors, faster and more reliable sample changers, and now the advent of fourth-generation synchrotrons, which deliver unprecedented photon flux and smaller beam sizes thanks to reduced source emittance. These advances have driven the development of new methods and protocols for data collection.

At IRELEC, we identified an opportunity to innovate by enhancing speed, accuracy, and flexibility in sample handling systems. Our objective was to improve overall beamline throughput while also enabling user-friendly implementation of advanced experimental procedures.

We developed a compact diffractometer combining fast and synchronous translations with a high-precision rotation stage. The design minimizes space requirements, simplifies beamline integration, and allows detectors to be placed at the shortest possible distance.

Main characteristics

- Vertical W-axis with < 200 nm sphere of confusion

- Fast switchover (< 2 s) between operating modes

- Automatic centering using the on-axis camera and automatic sample centering with x-rays (raster scan)

- 3-clicks centering feature also available

- Safe operation with absolute encoders on all axis

- Hand-shake operation with ISARA2 sample changer

- Digital twin and CAS for ultimate safety

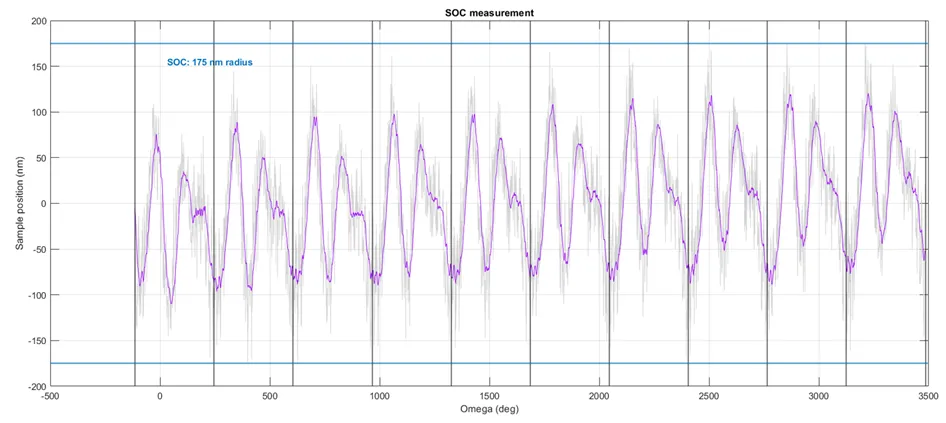

Vertical Ω-axis

Need: speed and accuracy.

Solution: air bearing vertically pointing up equipped with incremental Analog sin/cos encoder.

Outcome: Fast rotation and Small SOC

- Orientation : Vertical

- Sphere of confusion < 200 nm @ 100 °/s

- Maximum rotation speed = 1000 °/s

- Static Accuracy < ± 0.3 mdeg

- Dynamic Accuracy < ± 0.3 mdeg @ 10 °/s

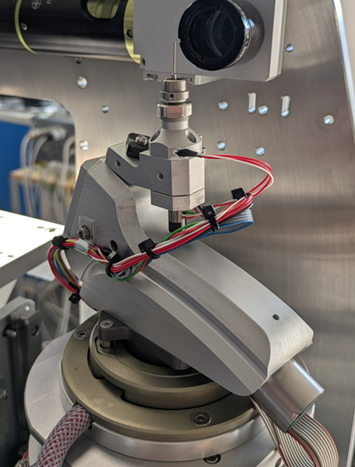

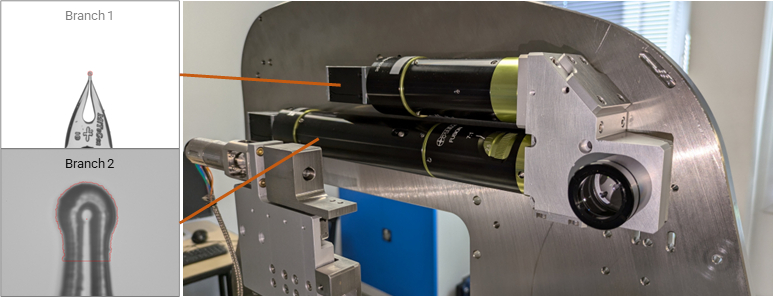

Kappa/Phi head

Need: Crystal precise (re) alignment for data quality optimization (due to crystal intrinsic properties).

Solution: 2-circles motorized Kappa Phi head. Compatible with Spine and non-Spine magnetic sample bases. Automated sample detection by an embedded laser sensor. Kappa end Phi integrating direct encoding for enhanced process reliability.

Thermal stability relying on resistance and PT100 probe for regulation. Temperature setpoint configurable.

Outcome: Precise 3D crystal positioning

Centring and Alignment stages

Need: Speed and accuracy for repeatable sample positioning and scanning. Execute raster scan and helical scan.

Solution: Two linear centring stages with fast brushless motors and absolute encoders.

We also integrated the stages so that level arms and related imbalances are minimized.

Outcome: Stable and reliable nanometric positioning and scanning stages.

Plate holder

Need: High-throughput In-situ (in plate) screening. In-situ experiment.

Solution: Ability to use all the available 96-well plates dedicated to in-situ experiment from Mitegen, Greiner and Molecular Dimension.

Integration of a plate detection system → allowing the use of automatic plate transfer using a robot sample changer.

Precise and repeatable positioning → X translation of the plate holder is relying on the centring stage. The vertical one on alignment stage. Each benefiting from an absolute encoder.

Outcome: Add a unique and new sample repositioning capability → Ready for advanced experiment workflow such as Mesh and Collect (Zander U. et al. 2015) or collect from a coordinate file.

Quick tool changer

Need: Versatility, adaptation to a growing diversity of sample holder and experimental setup. Being able to switch from crystals on loop collected in cryo-conditions to crystallization plate or any sample delivery device. Manipulation safe and simple even for a non expert.

Solution: Quick tool changer interface

Outcome: Allow the mechanical re-centring and electrical connection of different tools on top of the Centring stages. No tools required to switch from fixed sample holder to Kappa/Phi head or plate holder. Tools automatically identified by the diffractometer ensuring a high level of safety and integration. Allows implementation of efficient start-up procedures with enabling or disabling tools specific functionalities.

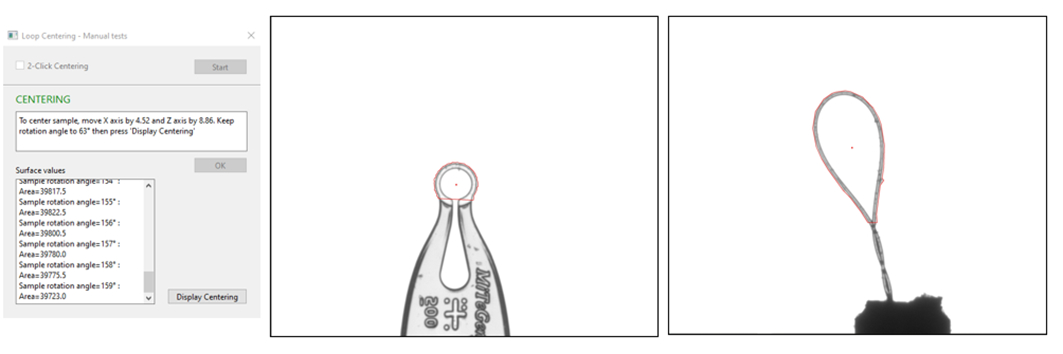

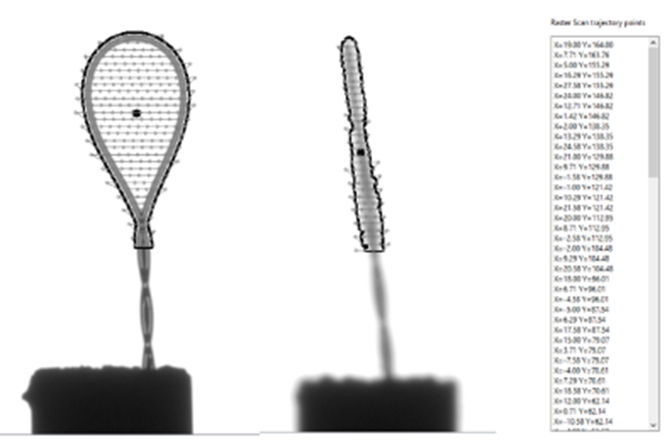

Automatic centring and Raster scan

Need: High-throughput, automation, efficient and flexible workflow. High-level software integration. Time to focus on experiment, not on instrumentation.

Solution: Automatic loop detection. Automatic centring . Automatic pre-orientation for raster scan (maximum loop surface).

Raster scan automatic setup trajectory. Helical scan.

Outcome: Automated workflow and advanced data-collection method work out-off the box from the HiDiff-X GUI. Or can be used via an API within an existing beamline software (MXcUBE or other high-level GUI).

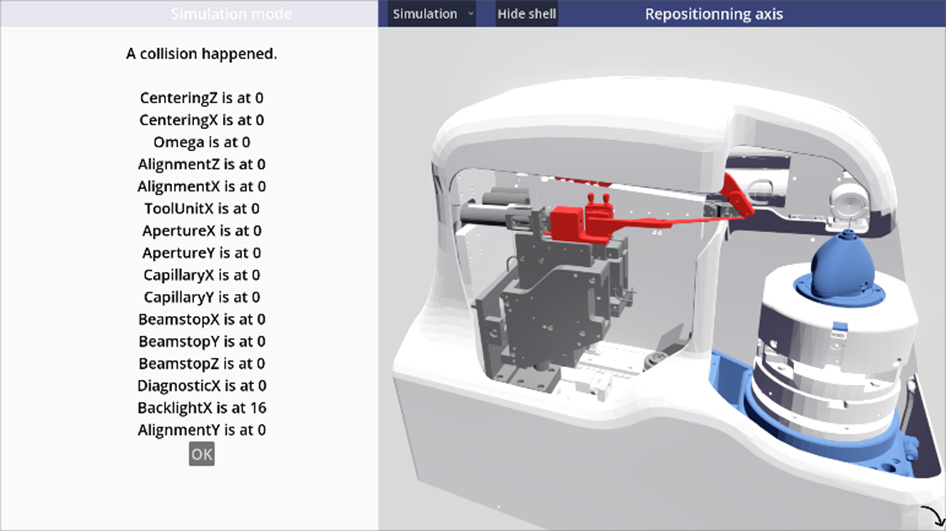

Digital Twin and Collision Avoidance System

Need: User friendliness, reliability. Adaptability to various tools and experimental conditions.

Solution: Digital twin. It’s an exact digital representation of the instrument and of its tools. All the motors and axis parameters are known. A simulation of the movement requested can be simulated prior to the actual movement or in real time (slightly earlier) to detect any collision.

Outcome: Through-put optimization, synchronous movement of multiples axes.